DOSING-WEIGHING

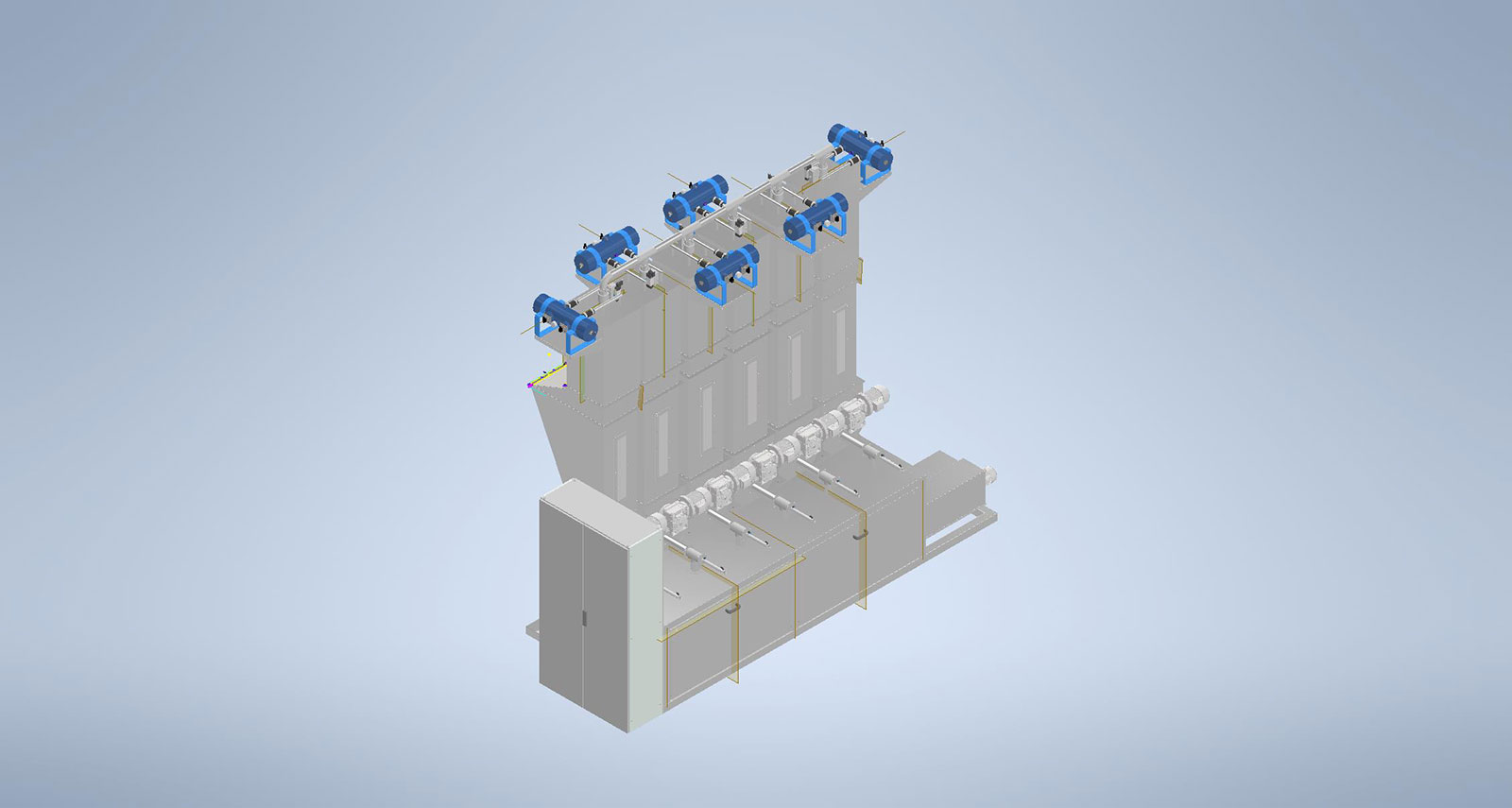

DOSING STATIONS FOR SOLIDS

Solid weighing stations can handle batch processes (multi-ingredient recipe) or individual materials. They are constructed in such a way to gain the maximum dosing accuracy, the optimal interface with the other parts of the production (kneaders, mixers, etc.) and ensure the protection of man and material. Their function can be either incremental weight or loss-in-weight. Their capacity ranges from 50kg up to 5,000kg.

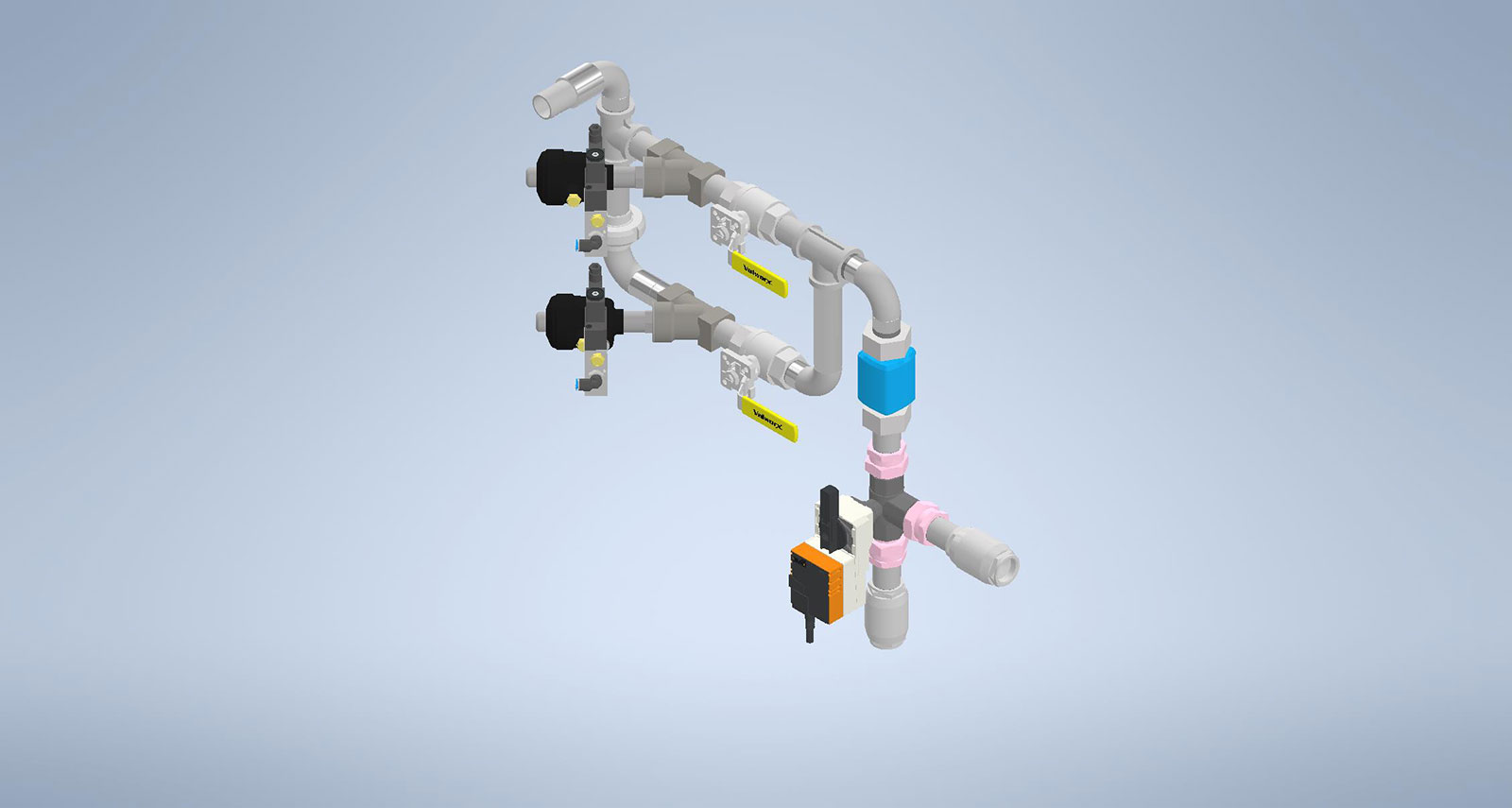

DOSING STATIONS FOR LIQUIDS

Liquid weighing stations can handle batch processes (multi-ingredient recipe) or individual ingredients. Especially for water, a temperature control can be performed. They are constructed in such a way to gain the maximum dosing accuracy, the optimal interface with the other parts of the production (kneaders, mixers, etc.) and ensure the protection of man and material. Their function can be either incremental weight or loss-in-weight. Their capacity ranges from 10kg up to 5,000kg.

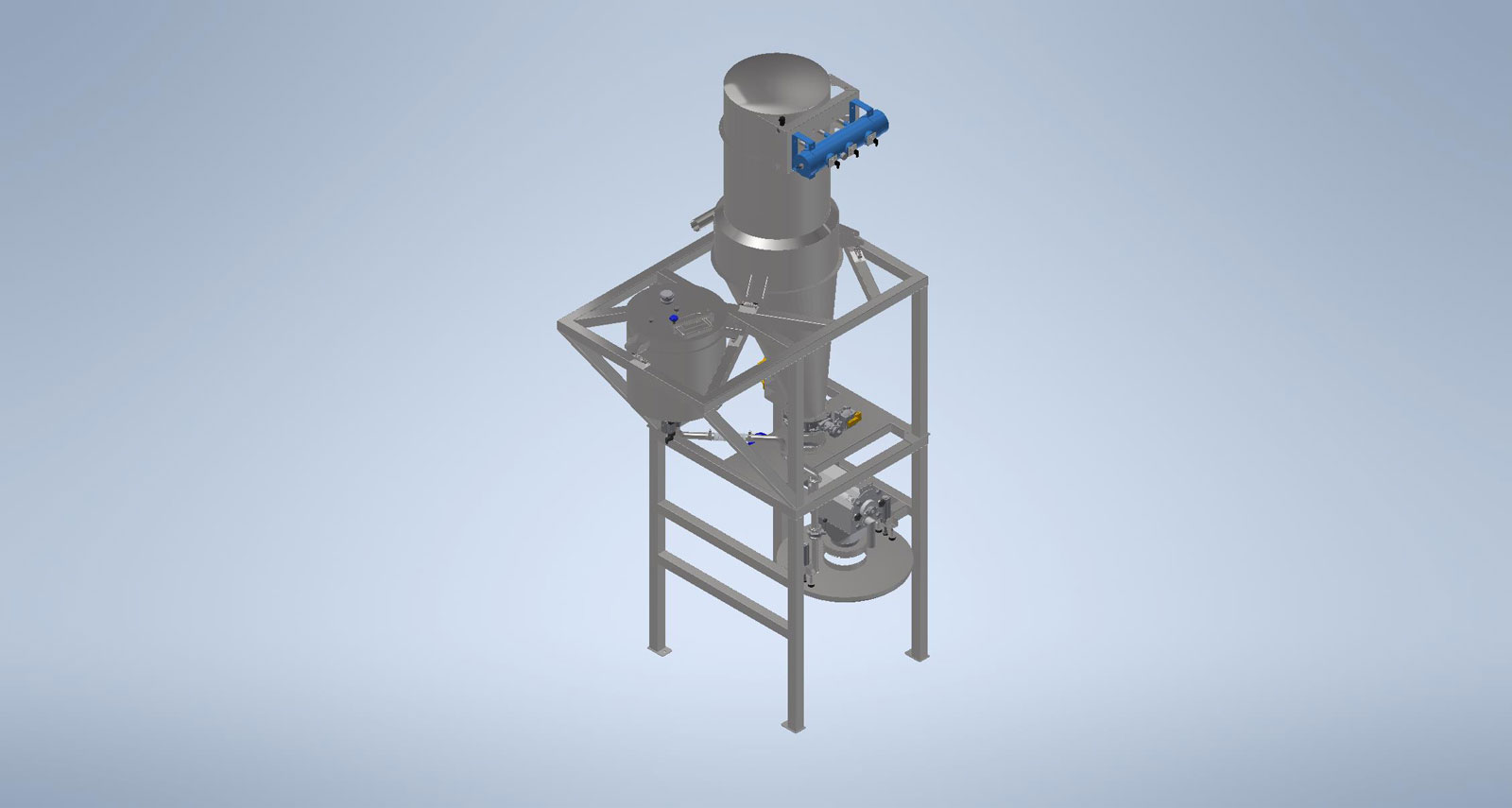

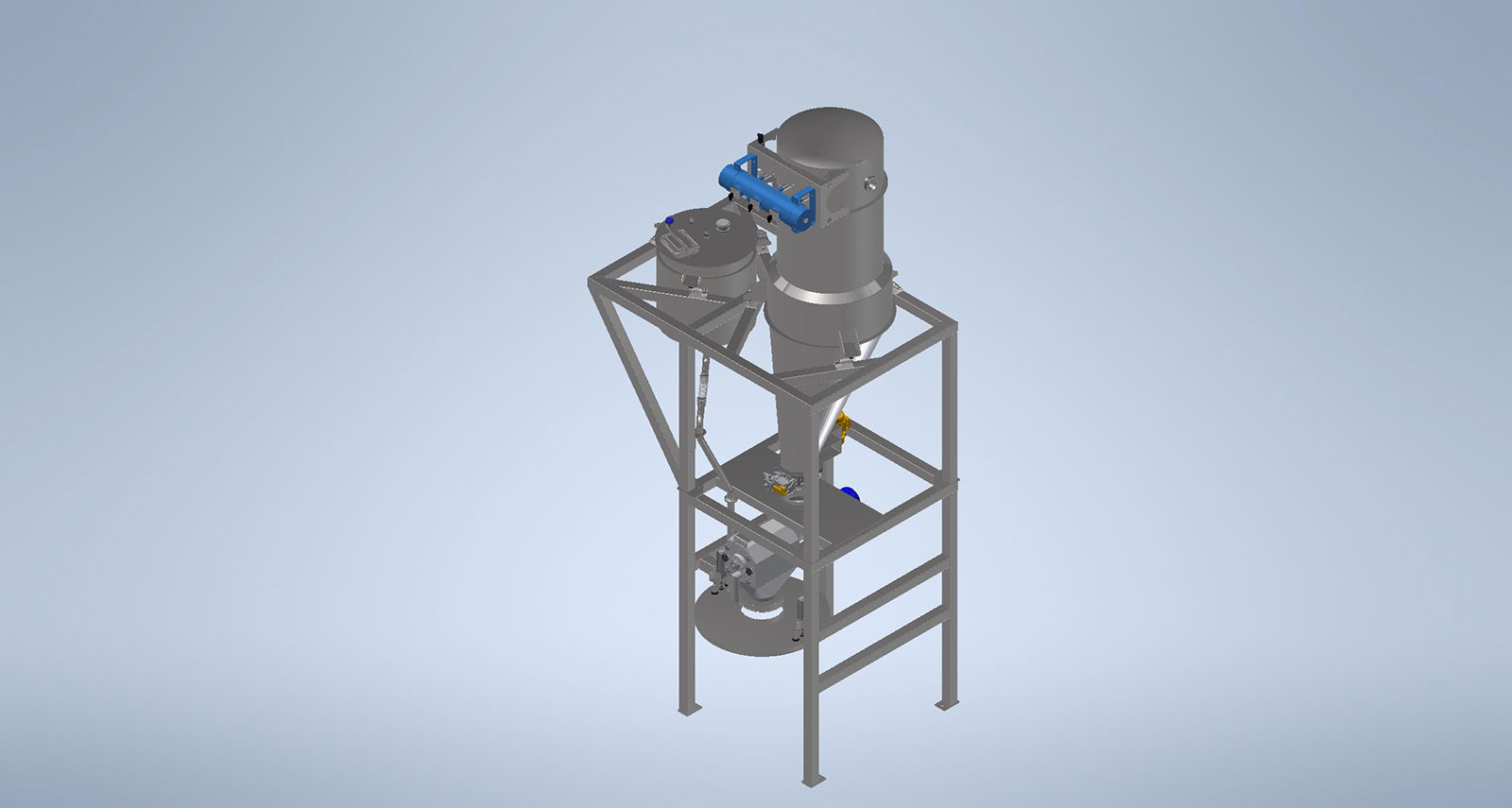

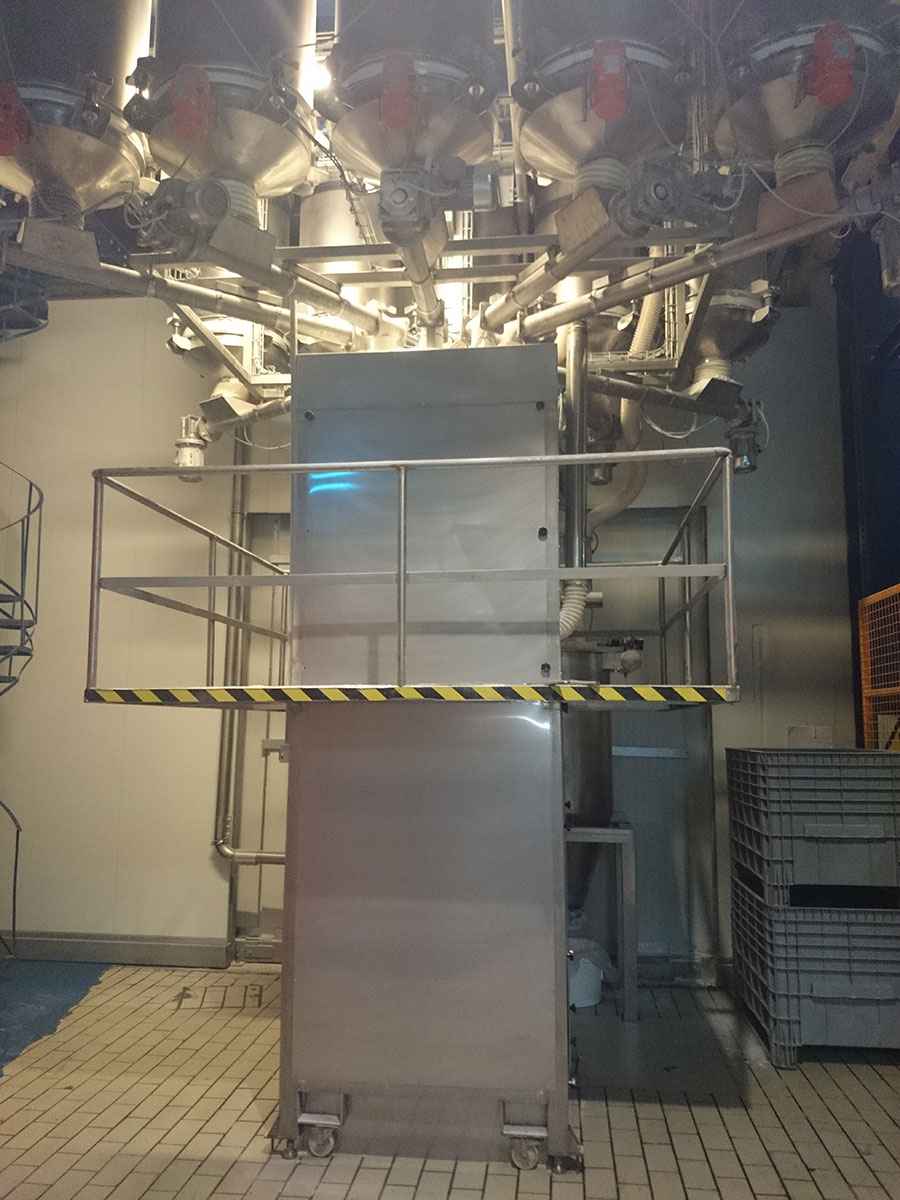

MICRO-DOSING CIRCULAR

Micro dosing units are suitable for managing additives such as sugar, salt, starch, ascorbic acid, improvers and other materials in powder form. They have a micro storage silo from 50kg to 1000kg with a dehumidification system if required, as well as a dedusting system during the loading process. To ensure the smooth flow of the material they are equipped with flow aids devices (vibrating cones or agitation systems).

The material is transferred to the scale using a screw conveyor customed designed according on the handling material and customer requirements. The maximum deviation of the dosing scale is ± 5gr ensuring the high accuracy of the dosing. They are constructed in such a way to gain the maximum dosing accuracy, the optimal interface with the other parts of the production (kneaders, mixers, etc.) and ensure the protection of man and material.

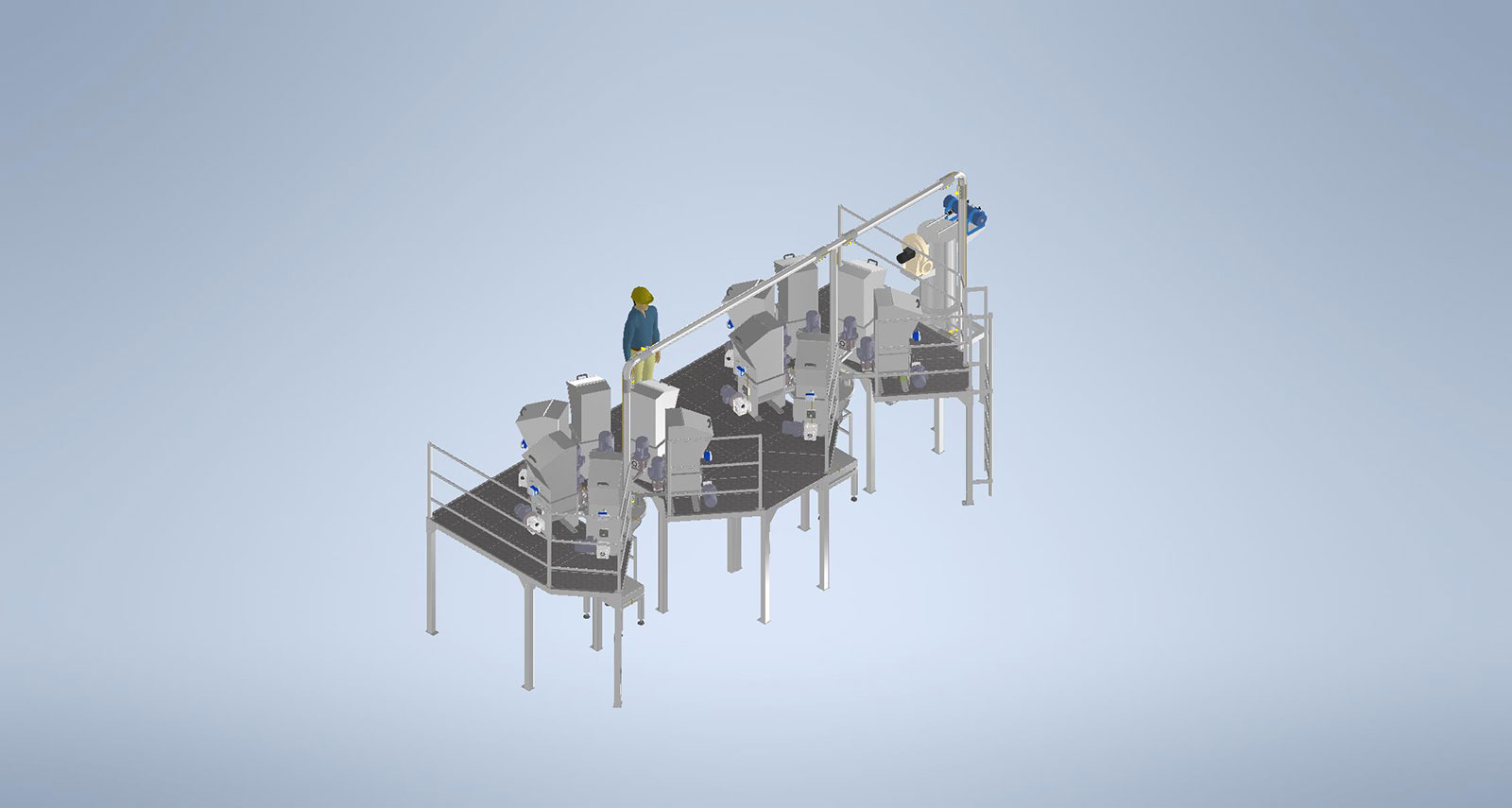

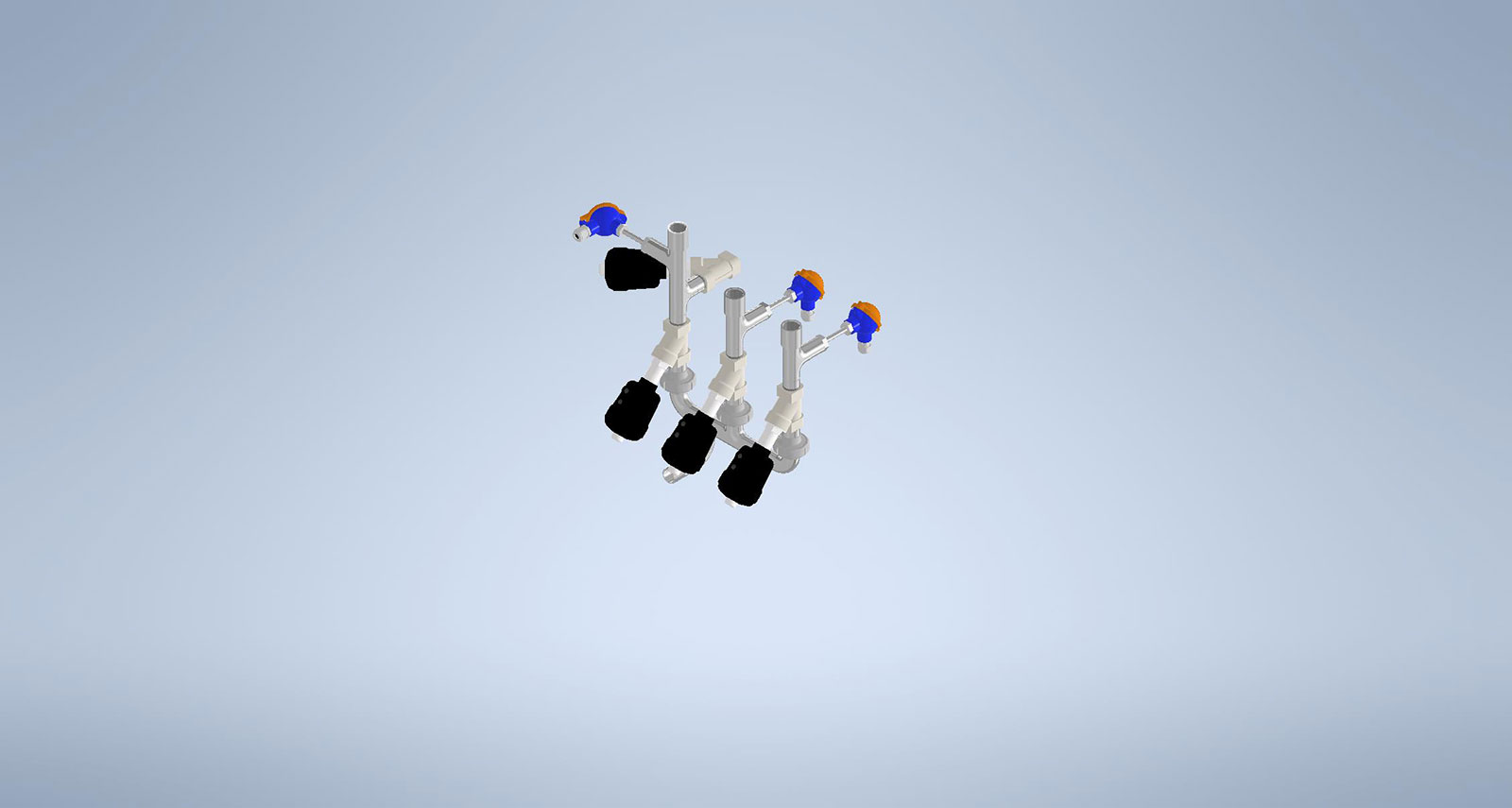

MICRO-DOSING LINEAR

Micro dosing units are suitable for managing additives such as sugar, salt, starch, ascorbic acid, improvers and other materials in powder form. They have a micro storage silo from 30kg to 500kg with a dehumidification system if required, as well as a dedusting system during the loading process. To ensure the smooth flow of the material they are equipped with flow aids devices (vibrating cones or agitation systems).

The material is transferred to the scale using a screw conveyor customed designed according on the handling material and customer requirements. The maximum deviation of the dosing scale is ± 5gr ensuring the high accuracy of the dosing. They are constructed in such a way to occupy the minimum possible space and ensure the protection of man and material.