SIEVING

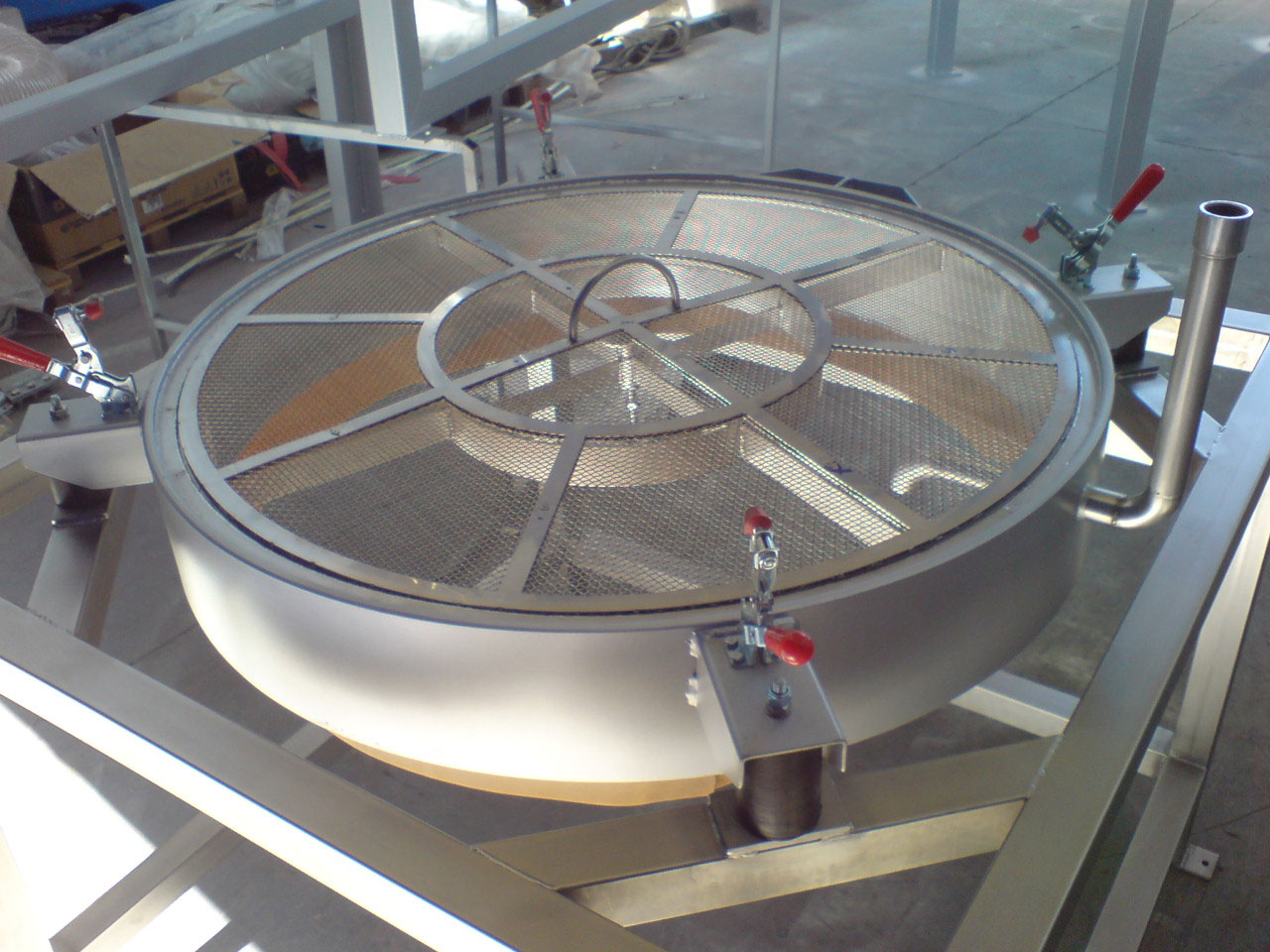

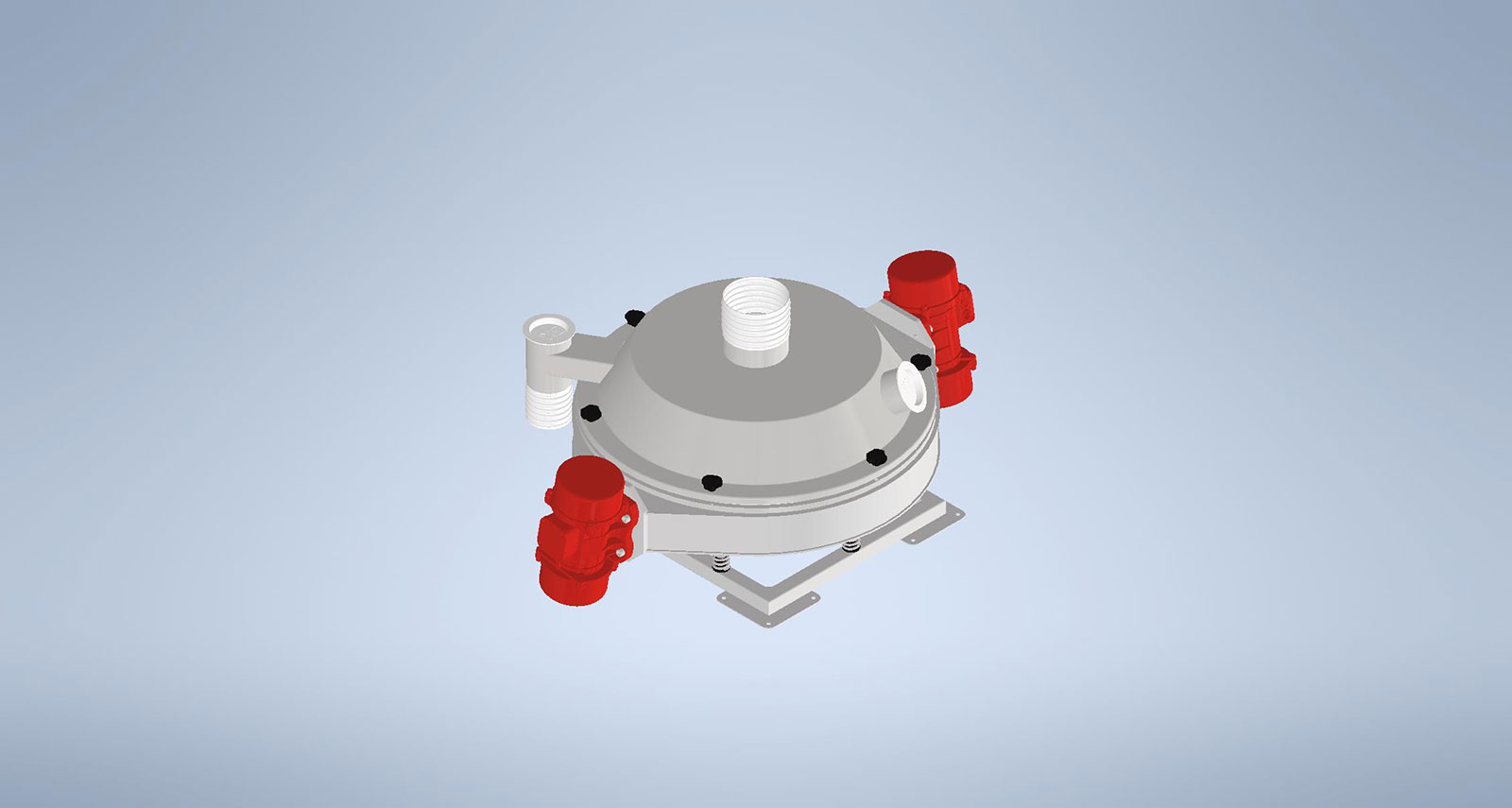

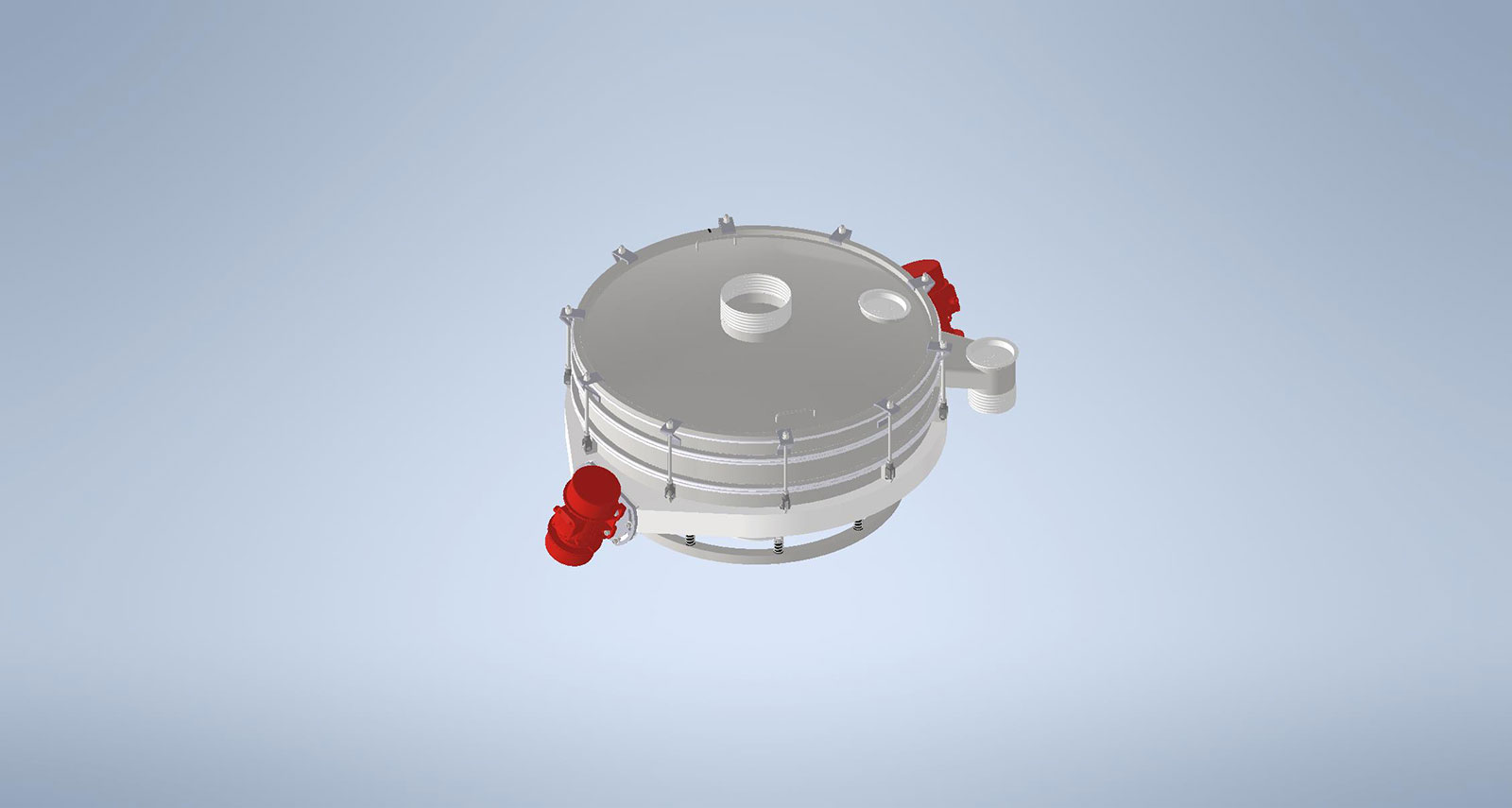

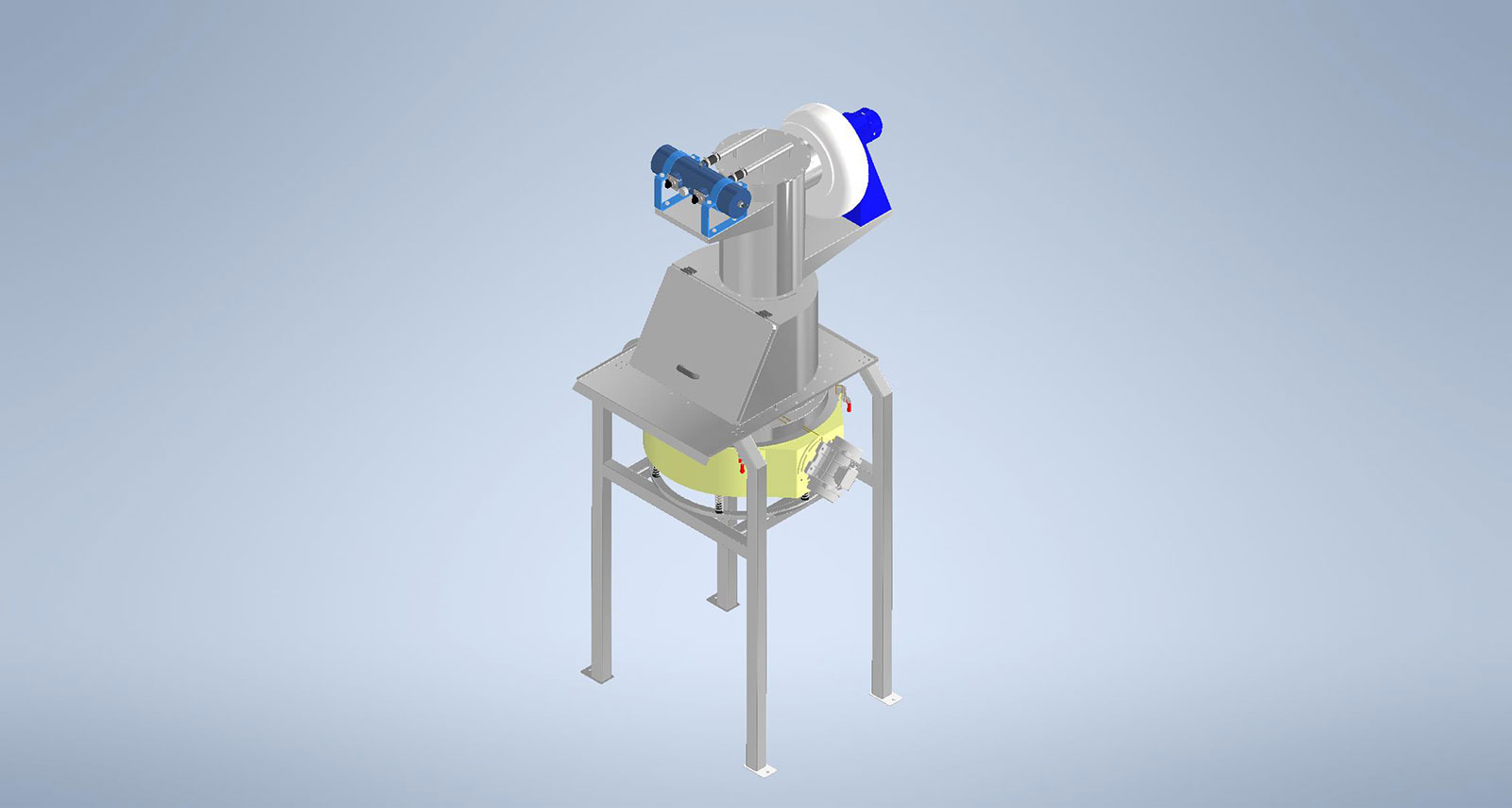

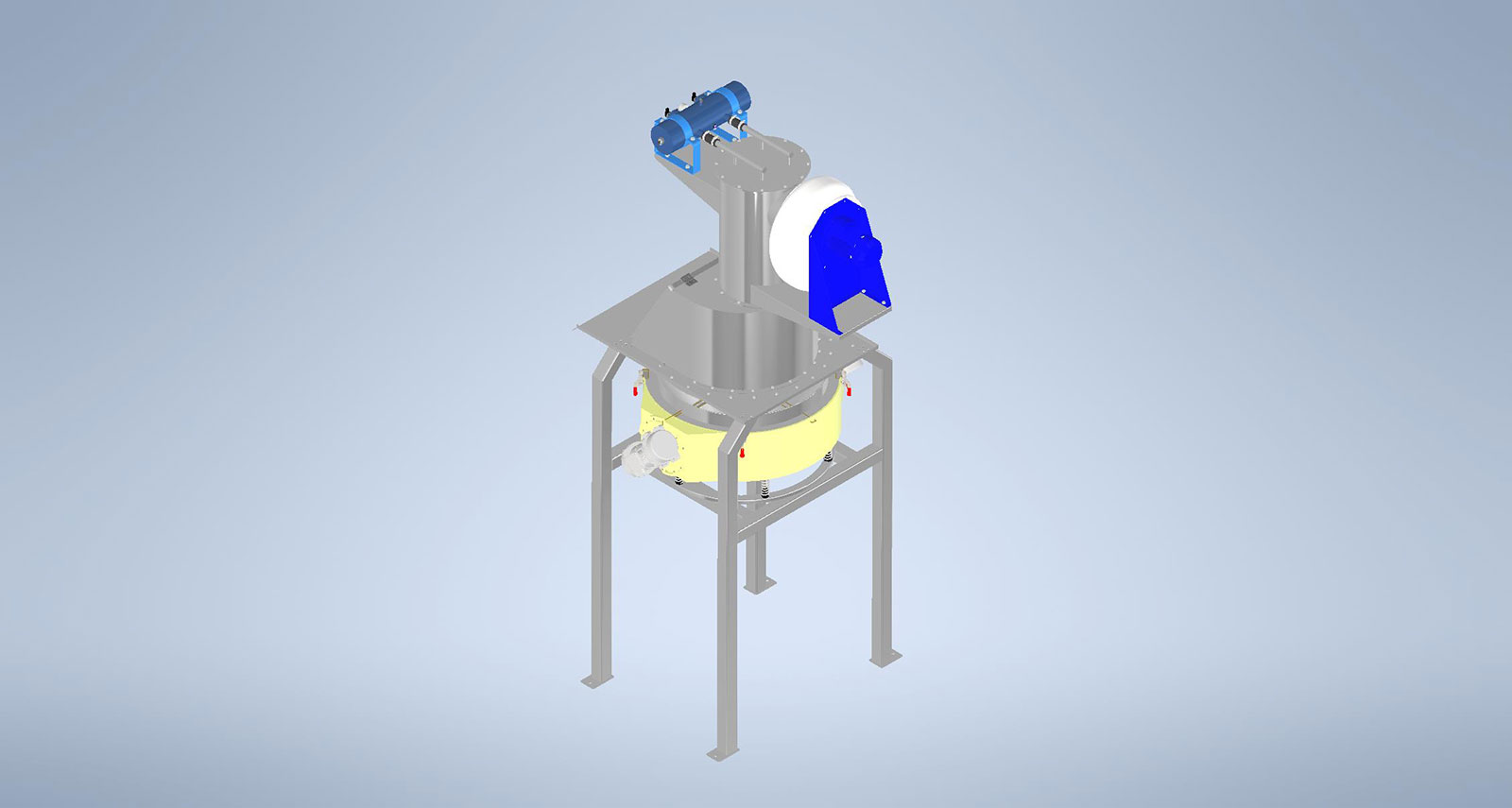

VIBRATION SIFTER

To ensure the quality of the product, it is necessary to separate agglomerates or foreign bodies from the powder materials. Vibrating sieves are suitable for flour, sugar and powder additives. Its main parts are the vibrating motor, the mounting system, the sieve and its cleaning mechanism. They are made of stainless steel AISI 304 or AISI 316.

All components that come in contact with the material are made of stainless steel and the elastic parts are certified for food industries. It has all the necessary safety devices for the protection of people and material. Their capacity ranges from 500 kg/h to 20,000 kg/h and the opening width of the sieve starts from 400 x 400 microns. Vibration sifters are suitable to be installed in Critical Control Points (CCP).

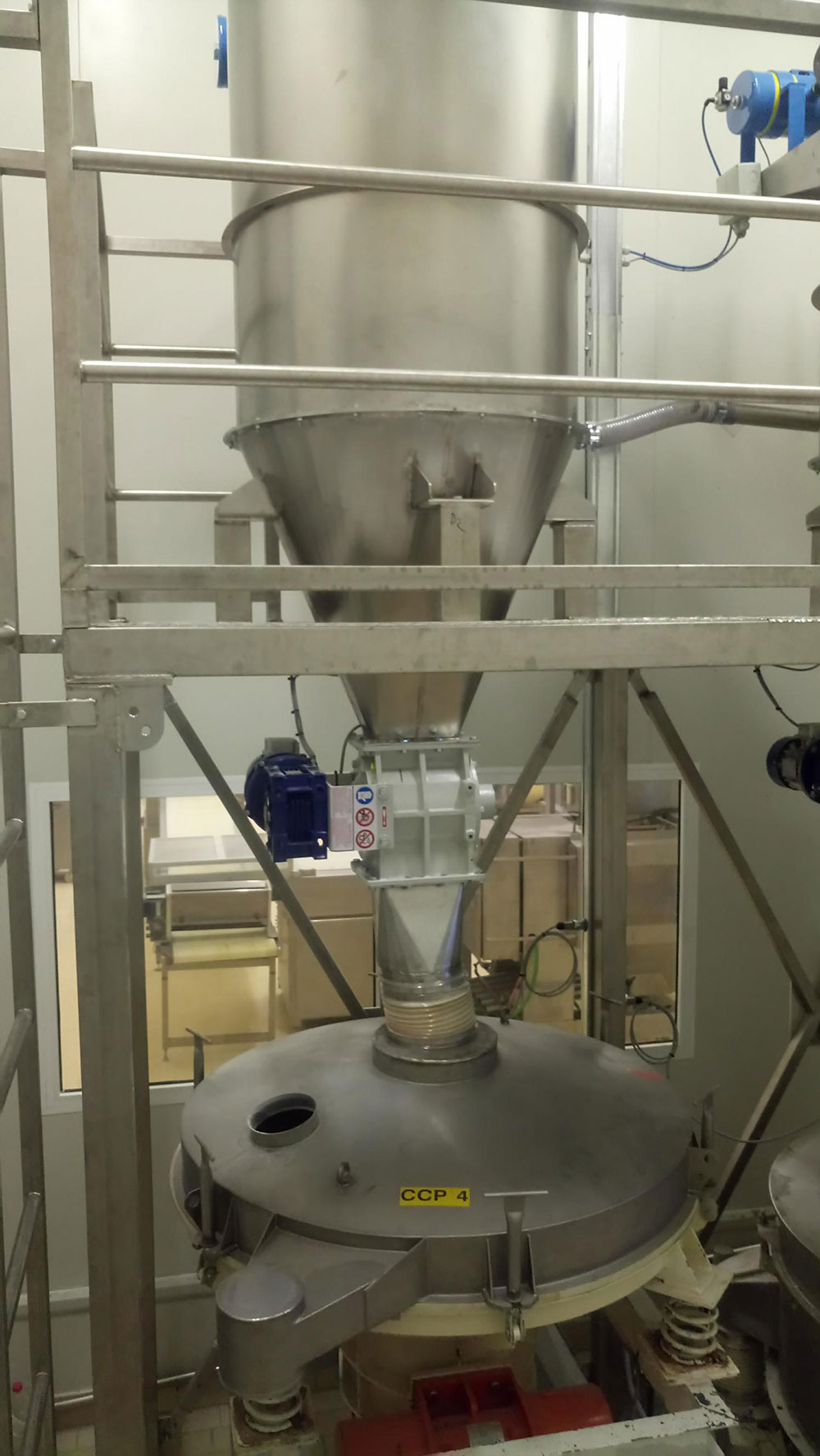

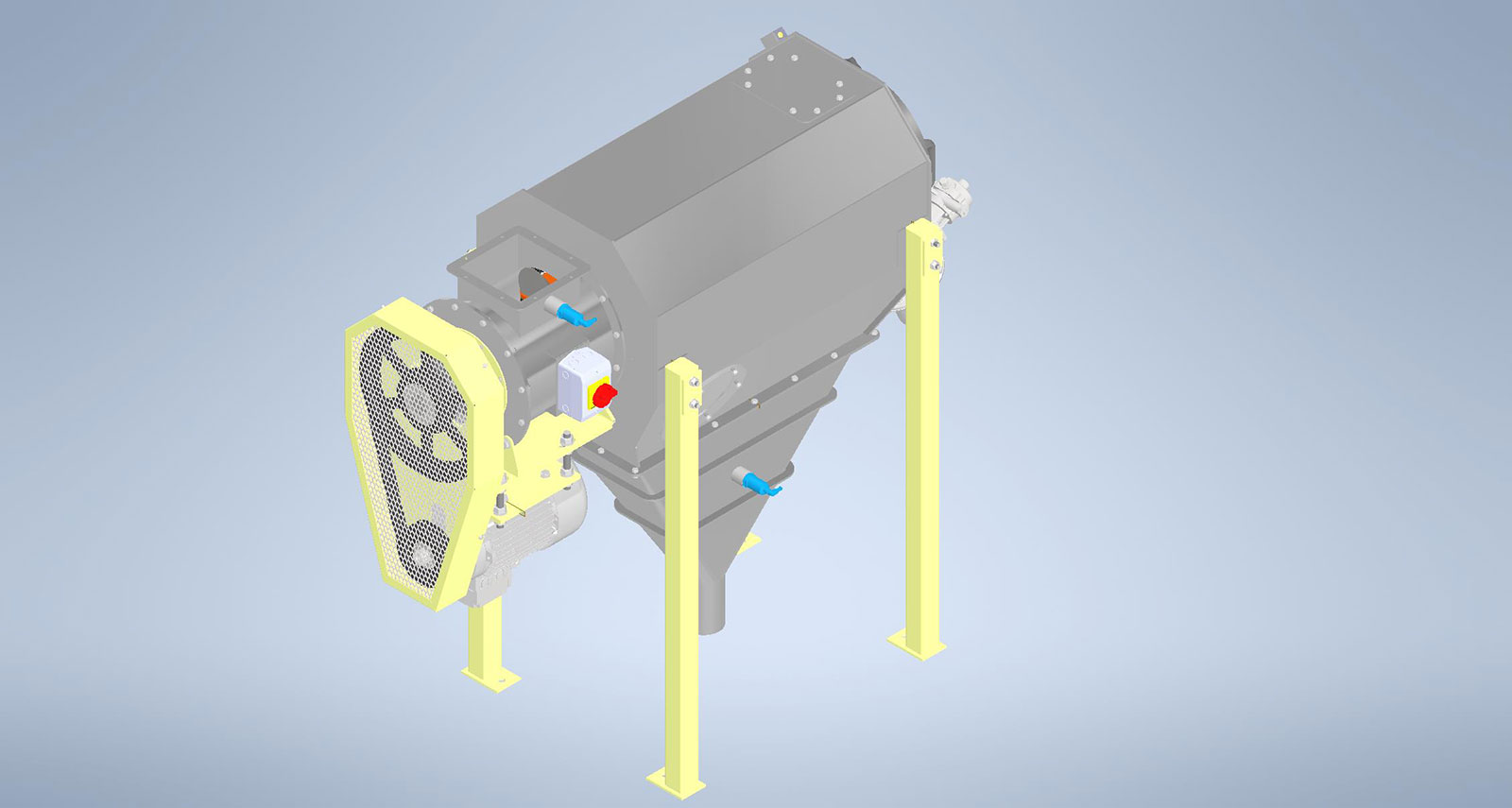

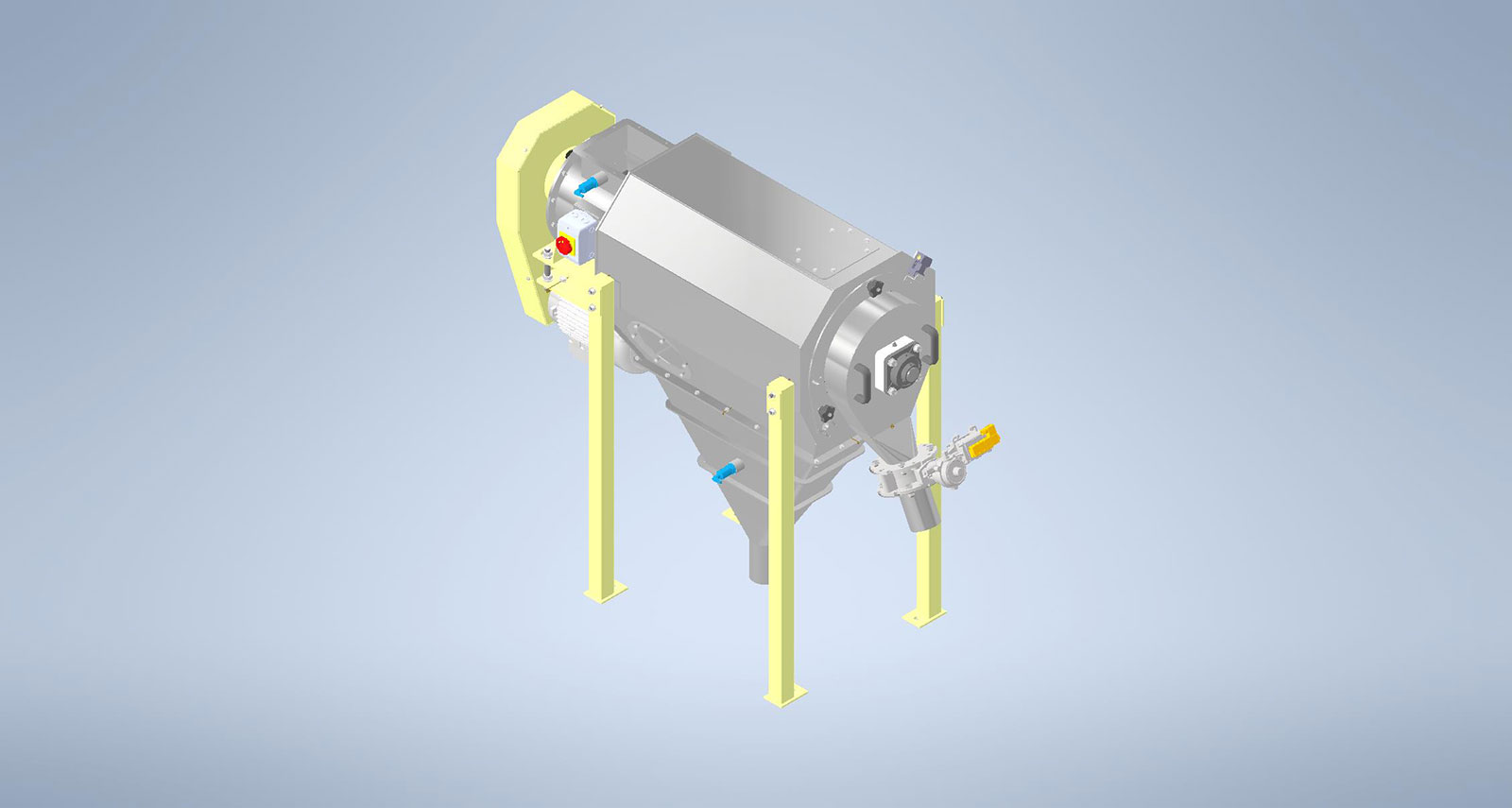

CENTRIFUGAL SIFTER

To ensure the quality of the product, it is necessary to separate agglomerates or foreign bodies from the powder materials. Centrifugal / rotary sieves are suitable for flour, sugar and powder additives. They are also suitable for integration into air pneumatic conveying systems. Its main parts are the high-speed motor, propulsion screw, the pallet with blades and the cylindrical sieve. They are made of stainless steel AISI 304 or AISI 316.

All components that come in contact with the material are made of stainless steel and the elastic parts are certified for food industries. It has all the necessary safety devices for the protection of people and material. Their capacity ranges from 500 kg/h to 10,000 kg/h and the opening width of the sieve starts from 600 x 600 microns. Vibration sifters are suitable to be installed in Critical Control Points (CCP).

MAGNETS

To ensure the quality of the product, magnets are used in order to separate granules or filings of iron from the powder materials. The magnets are suitable for flour, sugar and powder additives. They can be placed in pneumatic conveying lines or in free flow points of the material. Their main parts are the magnetic bars and their housing construction.

All components that come in contact with the material are made of stainless steel and the elastic parts are certified for food industries. It has all the necessary safety devices for the protection of people and material. Their magnetic induction ranges from 9,000 Gauss to 14,000 Gauss.