CONVEYING

PNEUMATIC CONVEYING SYSTEMS

The air pneumatic conveying system creates a mixture of air and material and drives it through a pipeline network to the desired point, without particular restrictions in height and distance. The air conveying system is one of the most flexible material handling systems. These systems do not require special maintenance because they have minimal components and moving parts. With new pneumatic conveying technologies, the energy footprint of the facility is kept to a minimum.

All components that come in contact with the material are made of stainless steel and the elastic parts are certified for food industries. The capacity of the system ranges from 0.5 tn/h to 30 tn/h for materials such as flour, sugar, salt and any other material in powder or granular form with a bulk density less than 1.5 kg/lt.

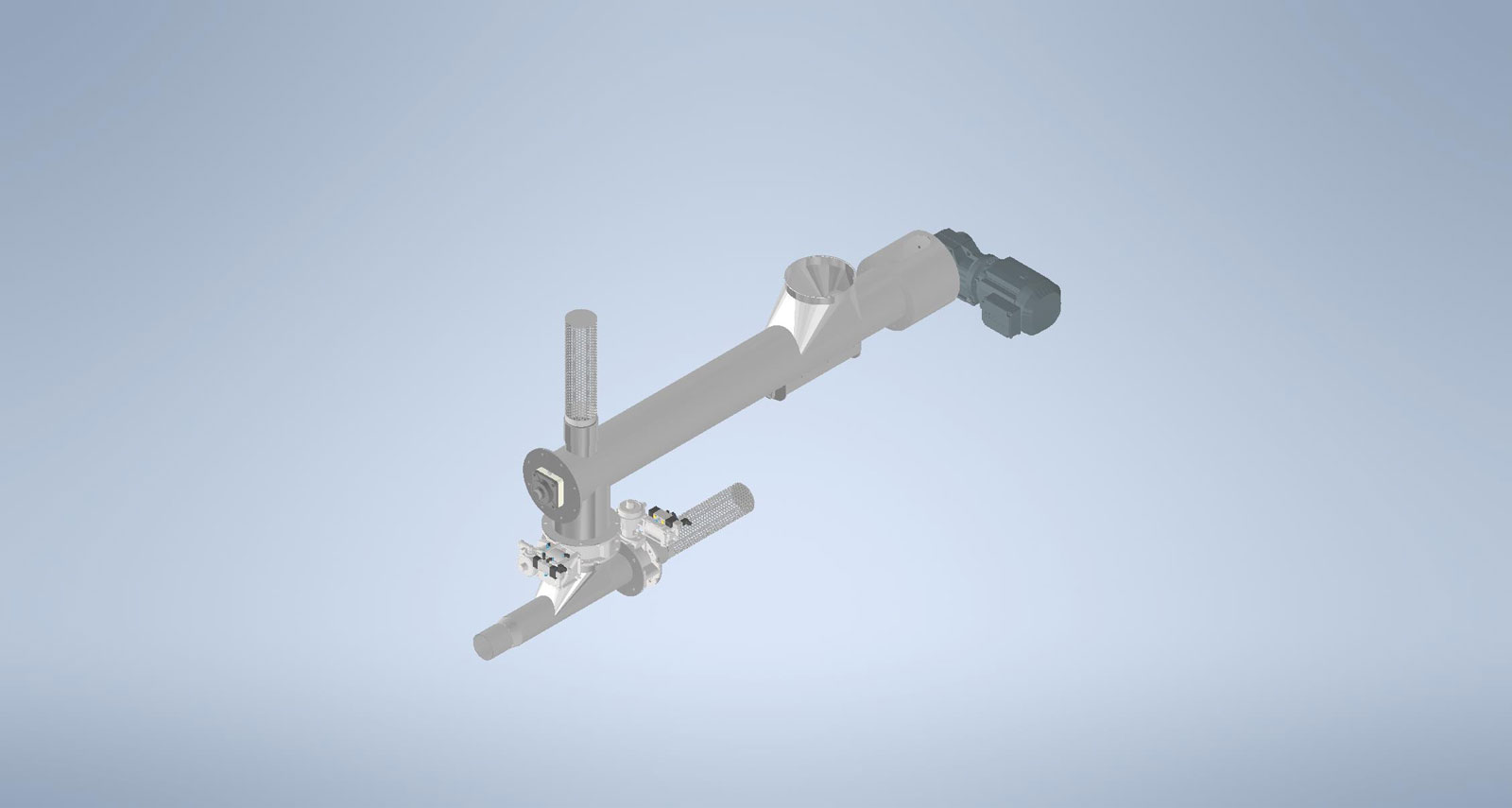

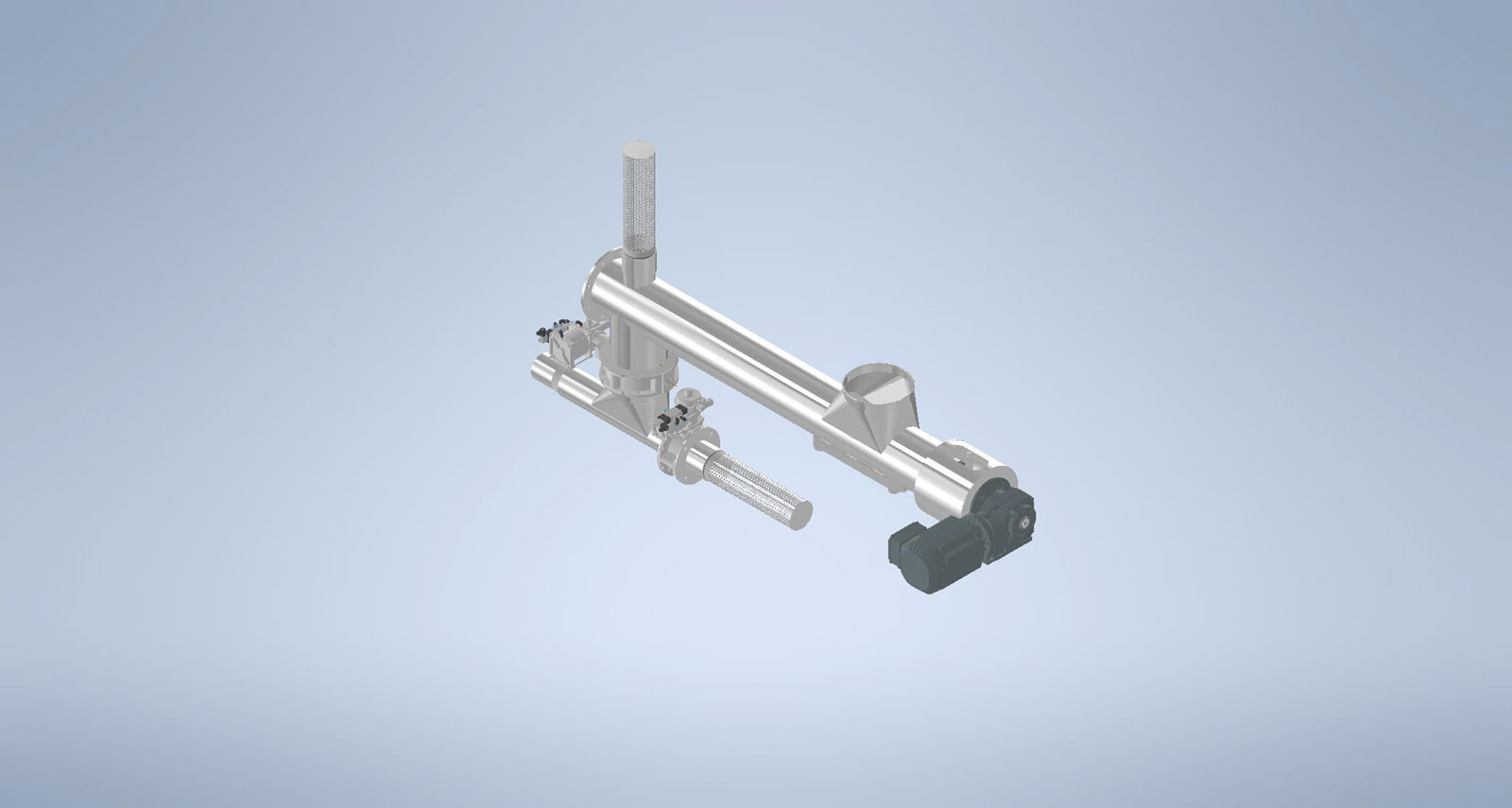

SCREW CONVEYOR

The screw conveyors are suitable for conveying material over short distances of up to 6 meters and can ensure a stable supply when required. All components that come in contact with the material are made of stainless steel and the elastic parts are certified for food industries. Their capacity ranges from 0.5 tn/h to 40tn/h. They are equipped with all the necessary safety devices for the protection of people and material.

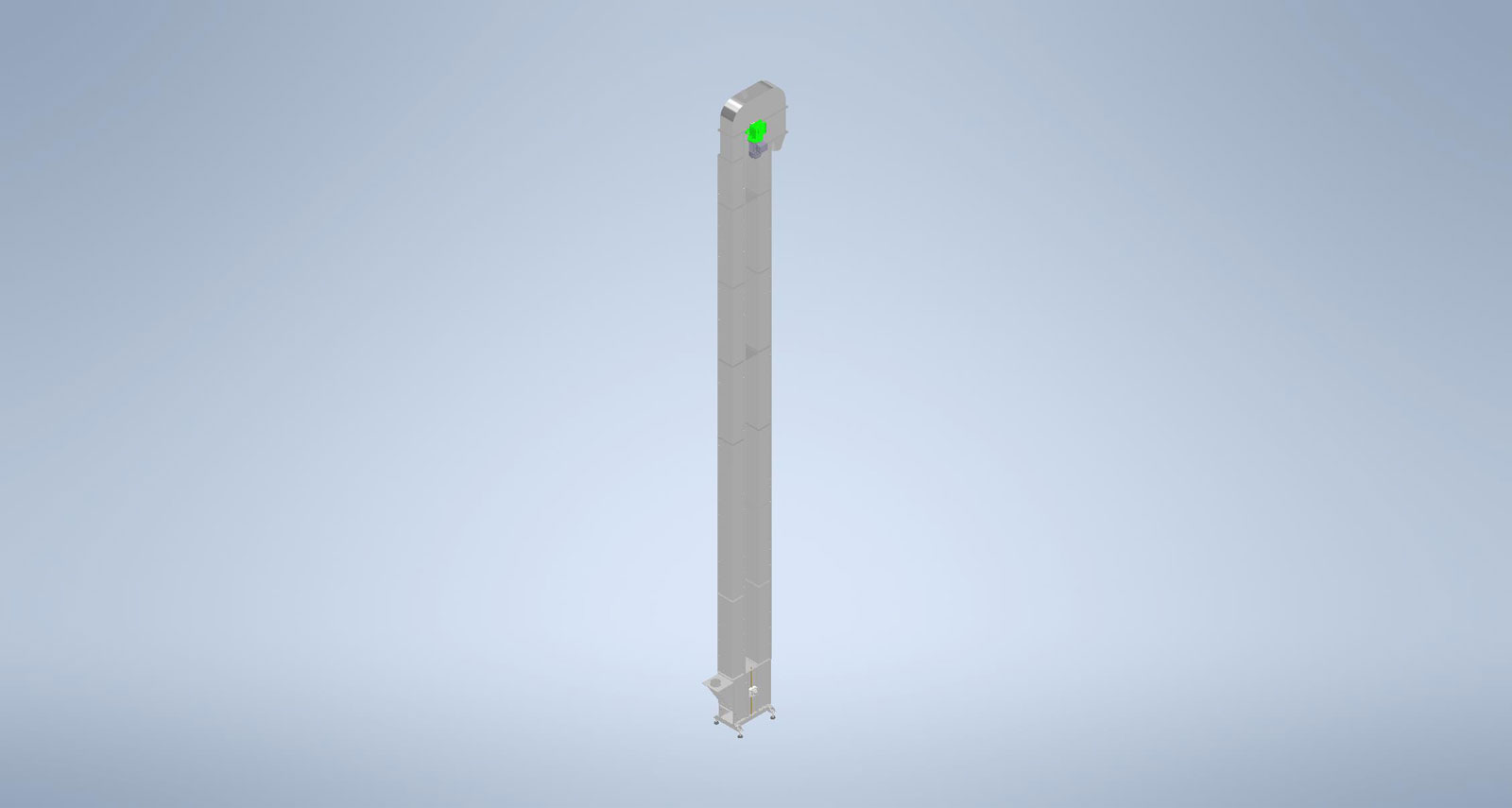

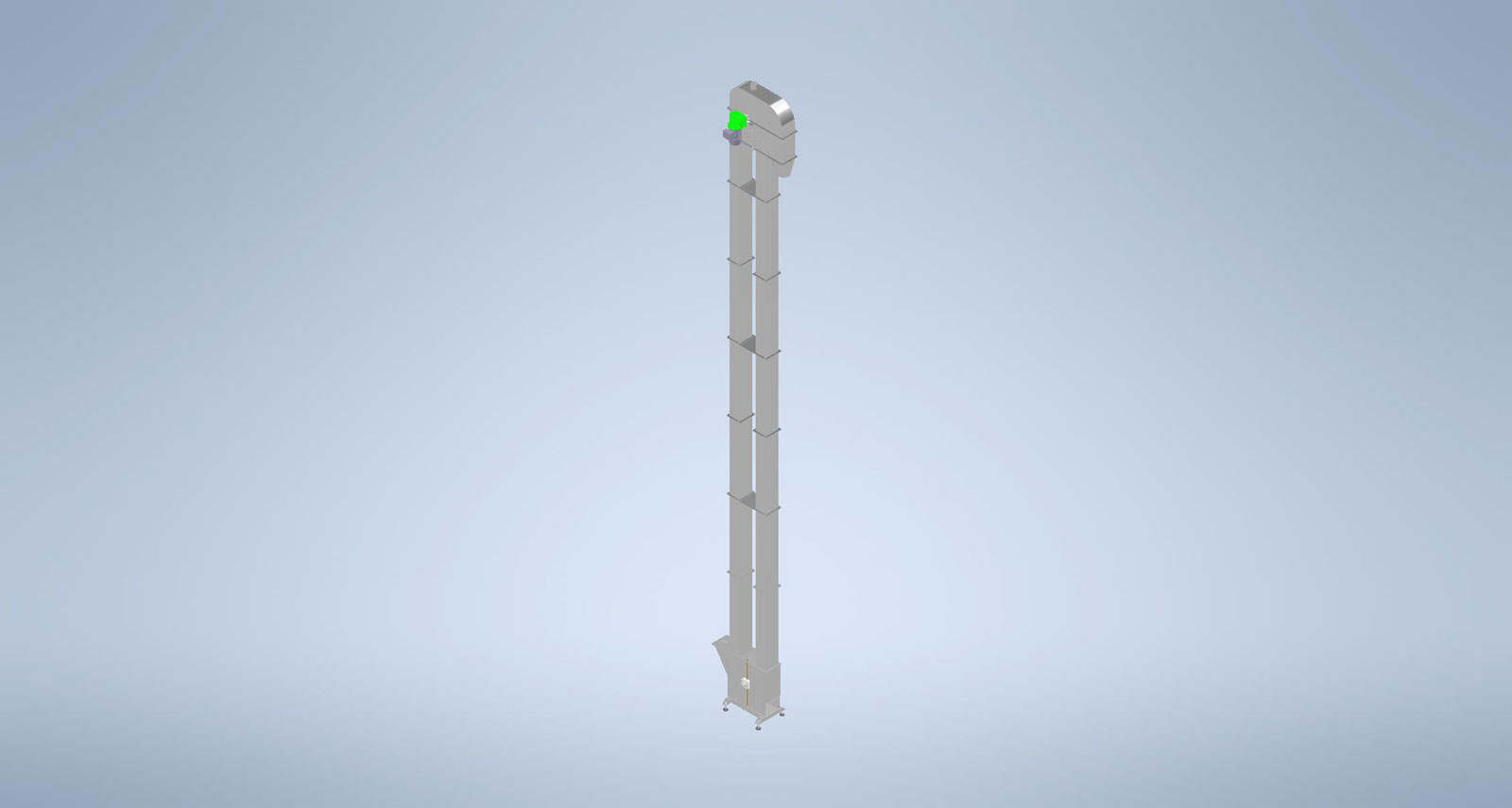

BUCKET ELEVATOR

Bucket Elevators are suitable for the vertical lift of materials from a lower point to a higher one. Its capacity ranges from 10 tn/h up to 100 tn/h. The energy footprint of the elevator is very low.The buckets are made of stainless steel or plastic suitable for food depending on the handling material. Its construction is made of stainless steel AISI 304 or AISI 316 and has all the necessary safety devices for the protection of people and material.

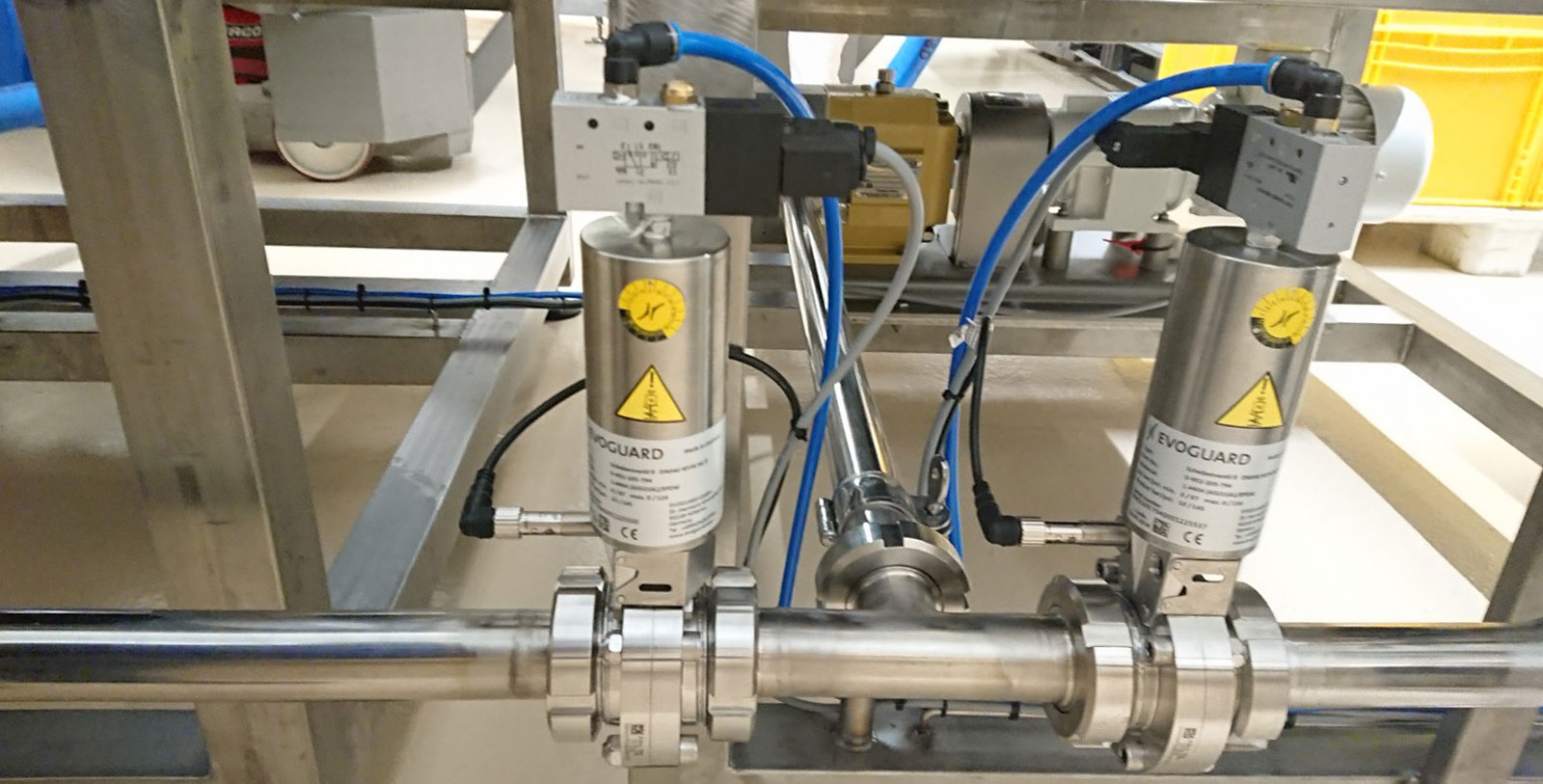

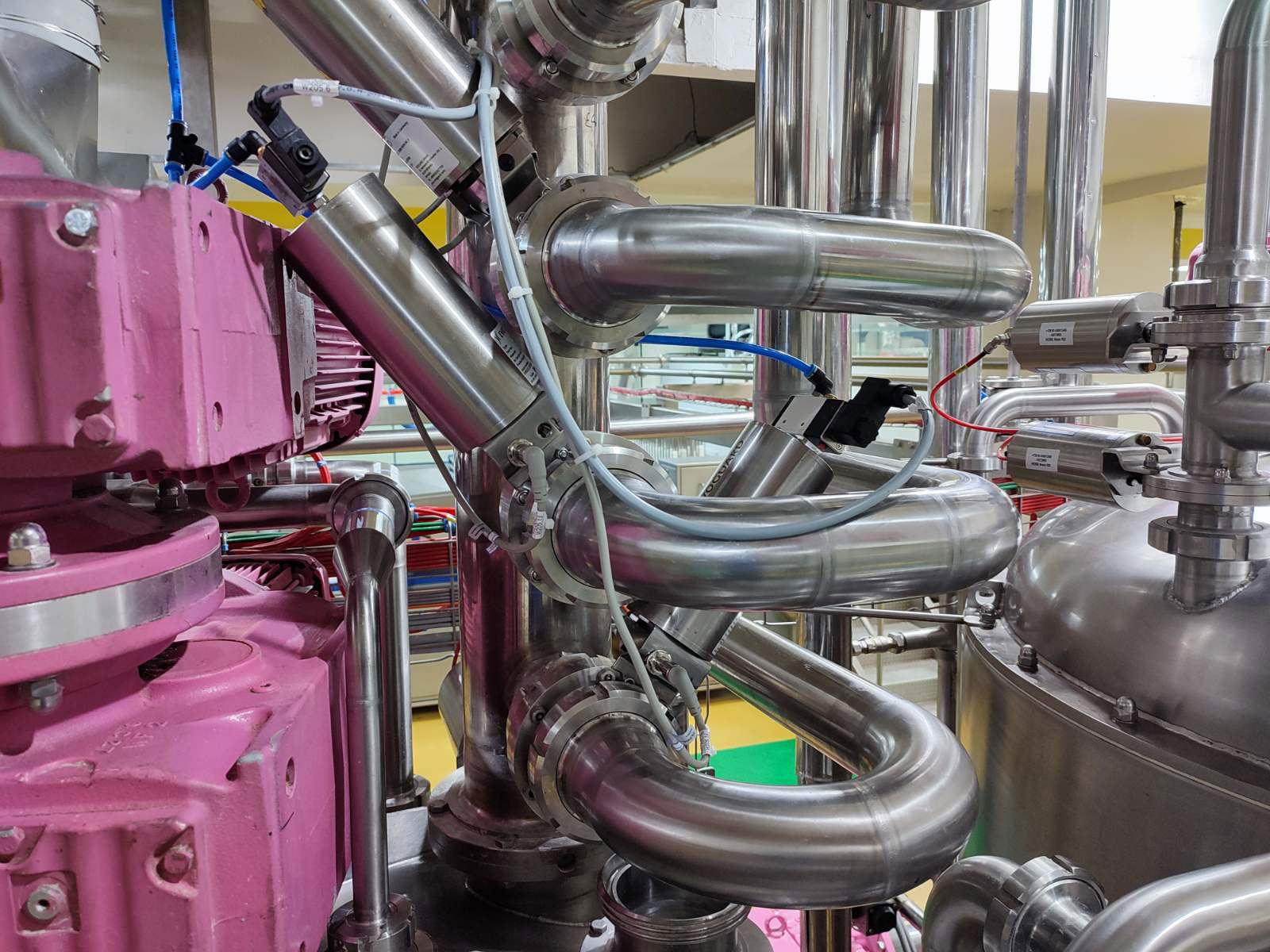

LIQUIDS NETWORKS

PRAXIS ENGINEERING SILO SYSTEMS can supply AISI 304 or AISI 316 stainless steel networks, suitable for the handling of liquid materials. They are made in such a way that they can be easily connected to CIP (Clean in place) systems and the welds are made in an inert environment (ARGON) by certified welders and the components used such as DIN 11851, are certified for the food industry. With the use of specialized pumps can be managed liquids used in the food industry with a wide range of viscosity and capacity.